Digitalization

Digitalization opens up completely new possibilities for textile manufacturers in the areas of management, innovation, production, maintenance & repair and quality. The latest solutions for this and their use in practice are presented in this section.

Manage digitally,

enhance efficiency

with the DPM for warp knitting

Interview on the launch of KM.ON's new DPM at ITM 2024 with Yevgeniya Nedilko, Cluster Lead Operational Excellence

Read more

A game changer in warp knitting shop floor management

The Digital Production Management (DPM) from KM.ON will be officially released at ITM 2024

Read more

Quality control on a new level - the new AI-based Quality Monitoring System (QMS)

KM.ON launches its pioneering QMS for warp knitting machines

Read more

New business momentum for the Turkish warp knitting industry

A highly flexible, efficient tricot machine and textile innovations with market potential - the KARL MAYER exhibition at ITM 2024

Read more

New 2024 training dates

CREATE DESIGN online courses or creative minds in the knitting industry

Read more

Gateway to 3D Knitwear Innovation

Revolutionizing Knitwear Design with CREATE DESIGN by KM.ON and STOLL

Read more

The design makes the difference

Knitwear Lab relies on top creative performance and the CREATE PLUS patterning software

Read more

More fun and efficiency in learning

Kent State University School of Fashion relies on CREATE PLUS

Read more

Tradition meets digitalisation

Astrifa GmbH relies on CREATE PLUS for the production of its knitted traditional clothing

Read more

Raschel machines with more diversity and a digital generation HKS with performance upgrade

Warp knitting exhibition of the KARL MAYER GROUP at ITMA, 08. – 14.06.2023, Fiera Milano, Hall 4 B119

Read more

Warp preparation innovations for sample warping and indigo dyeing

At the ITMA, the KARL MAYER GROUP will be showing solutions for the topics that move its customers, 08 - 14.06.2023, Fiera Milano, Hall 4 B119

Read more

Innovations from STOLL for more benefits in the flat knitting sector

Exhibition of the KARL MAYER GROUP at the ITMA, 08. - 14.06.2023, Fiera Milano, Hall 4 B119

Read more

Master the Change with digital solutions

At ITMA, the KARL MAYER GROUP will be showing how to take advantage of the opportunities offered by digitalization - 08-14.06.2023, Fiera Milano, Hall 4 B119

Read more

Digital knitwear design meets artistic creativity

Fostering future talent in the fashion industry through k.innovation CREATE DESIGN

Read more

What will happen in the next 15 years?

The Presidents of the KARL MAYER Group's business units look to the future

Read more

A machine with many faces

KARL MAYER launches the HKS 4-M ON, the most flexible HKS 4 model in the world thanks to digital solutions

Read more

Patterning from the cloud

SwapKnit – KARL MAYER's first Smart Machine function revolutionizes the way of guide bar control

Read more

Transparency for efficiency

With new features, the k.management dashboard offers even more support for day-to-day work

Read more

Full service packages for machine operation

KARL MAYER’s Care Solutions packages provide greater freedom to concentrate on the core business

Read more

Warp knitting 4.0

Christof Naier, President of the Business Unit Warp Knitting at the KARL MAYER Group, explains the digital future of warp knitting

Read more

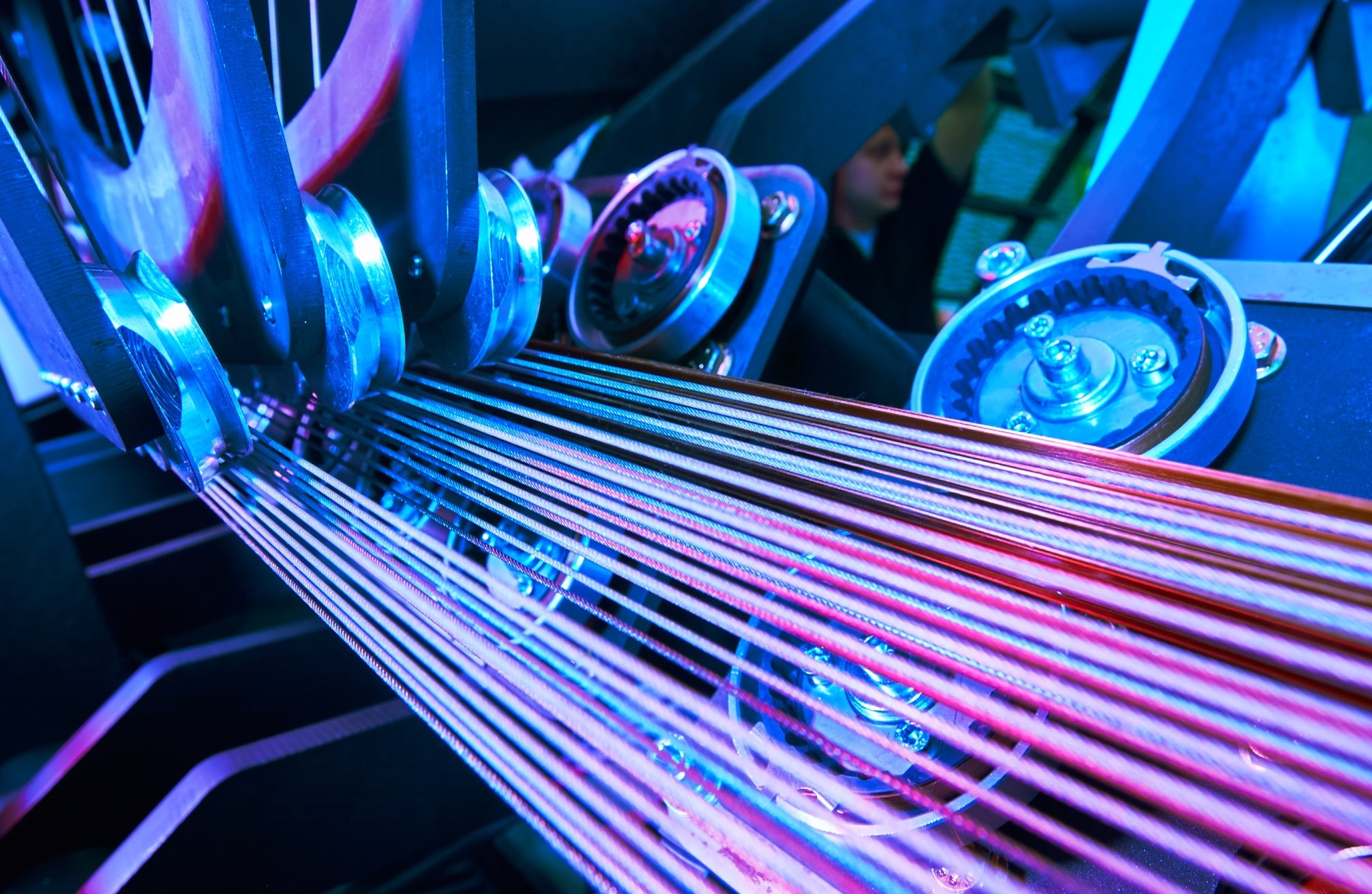

Quantum leaps in patterning

KARL MAYER’s pattern drive solutions have been setting standards since day dot

Read more