Warp Preparation

Machines for beaming and direct beaming, sectional warping and warp sampling, sizing and assembling as well as indigo dyeing equipment including creels - you will find news about production technology for the complete warp preparation for weaving in this section.

Clever energy-saving solution at no extra cost

With CASCADE, warp preparation saves money and CO2 emissions. Karl-Heinz Vaassen from KARL MAYER explains how this works

Read more

Steam ahead to save energy!

CASCADE - a KARL MAYER GROUP solution for verifiable inline energy recycling on sizing machines and dyeing systems

Read more

Prevention instead of aftercare when it

comes to warp quality

PROACTIVE-Warping for proactive quality management on the PROWARP® from KARL MAYER

Read more

More efficiency and sustainability for warp preparation

Inline energy recycling during drying, BLUEDYE for environmentally friendly indigo dyeing and innovations for less downtime - the KARL MAYER Warp Preparation for ITM 2024

Read more

Lots of visitors, good discussions, a look at the trends

Successful participation of the KARL MAYER GROUP at Techtextil, 23-26.04.2024 in Frankfurt am Main

Read more

To fly the flag in East Asia

The KARL MAYER GROUP is looking forward to a successful SaigonTex, April 10th - 13th, 2024, Hall A, Booth 1J-01 at the Saigon Exhibition and Convention Center

Read more

KARL MAYER TURKEY appoints General Manager

Toros Greenhalgh becomes General Manager of the new KARL MAYER subsidiary in Türkiye

Read more

Record interest from a market on the upswing

The KARL MAYER GROUP sums up the response from India to its exhibits at ITMA 2023

Read more

Warp preparation innovations for sample warping and indigo dyeing

At the ITMA, the KARL MAYER GROUP will be showing solutions for the topics that move its customers, 08 - 14.06.2023, Fiera Milano, Hall 4 B119

Read more

Care Solutions for perfect all-round support

KARL MAYER's Care Solutions offers set new standards in all aspects of machine operation

Read more

KARL MAYER extends its warp preparation portfolio

KARL MAYER GROUP acquires the yarn tensioner technology from APPALACHIAN ELECTRONIC INSTRUMENTS INC.

Read more

More weaving efficiency, less size add-on

KARL MAYER's PROSIZE® sizing machine has a convincing track record on the market

Read more

High performance, best reputation

PR Venketrama Raja, Chairman of Rajapalayam Mills, invests in KARL MAYER's ISOWARP and talks about it

Read more

Lotustex Textile invests in KARL MAYER's first LINK- MATIC® system

For automatic batch change on PRODYE®-S slasher indigo dye range

Read more

Pulling the right strings in the right place at the right time

Boost in demand for warp preparation equipment from KARL MAYER in Italy due to return of production to Europe

Read more

Cooperation with denim Brands

KARL MAYER is looking forward to working with leading denim brands

Read more

Environmental pioneer relies on GREENDYE by KARL MAYER

NIEN HSING buys the first GREENDYE by KARL MAYER unit

Read more

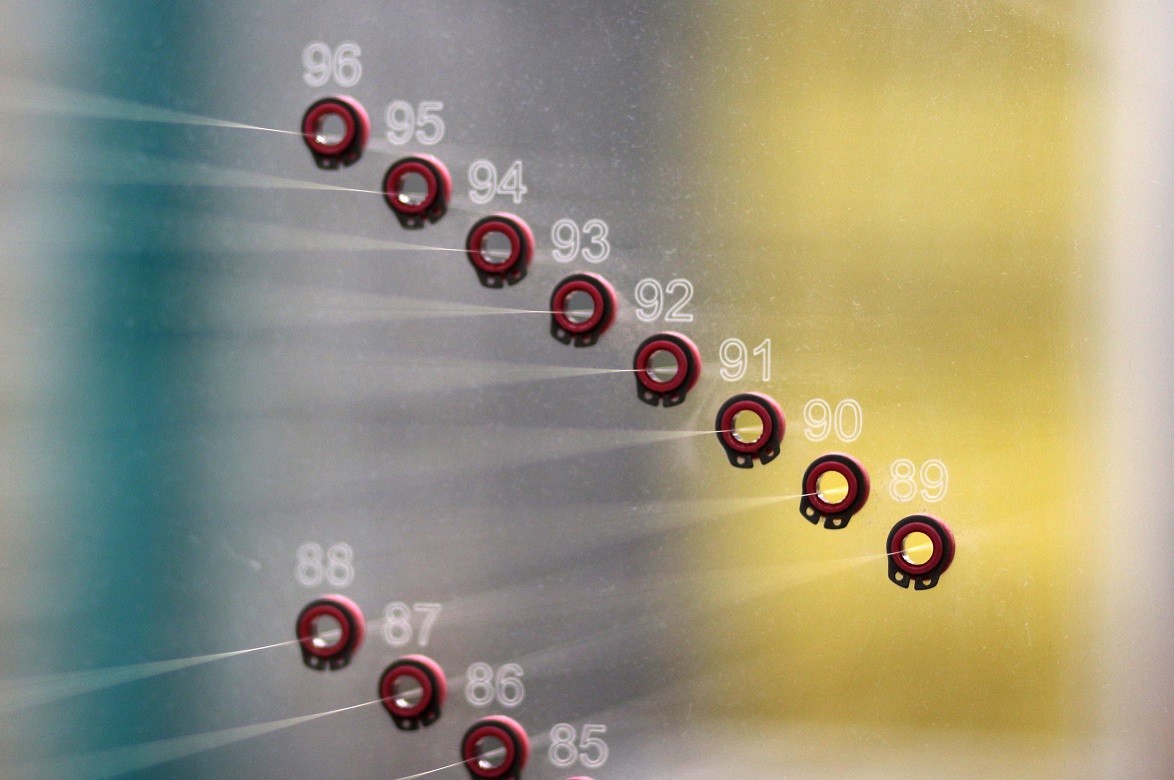

Magnetic power ensures correct tension

New version of the DISCTENS disc-type yarn tensioner offers even better performance

Read more

management change of KARL MAYER Warp Preparation

Roland Kohn retires, Enzo Paoli takes over

Read more

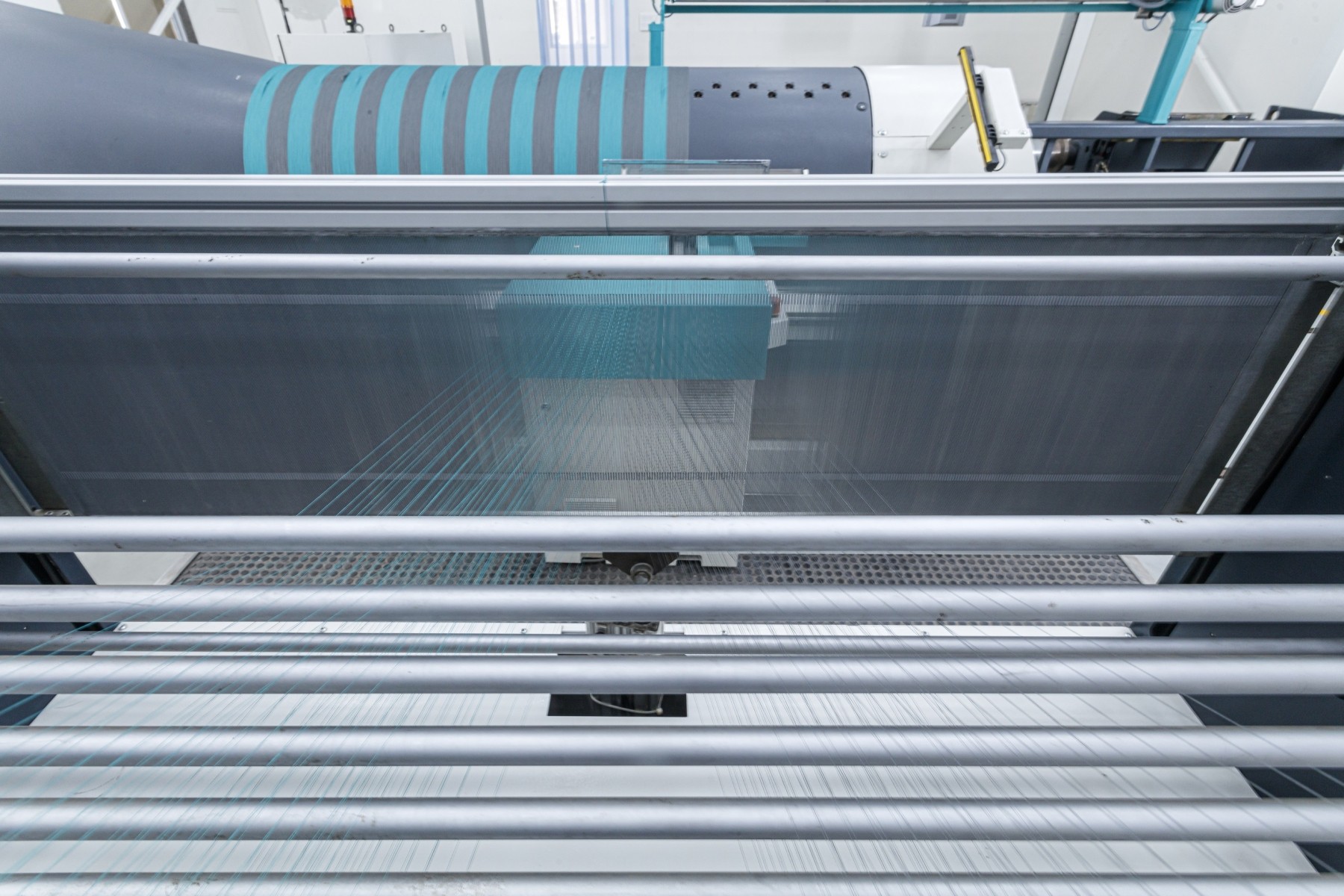

Warping using sophisticated technical solutions

The new PRODIRECT® – the efficient way to high-quality warper's beams

Read more

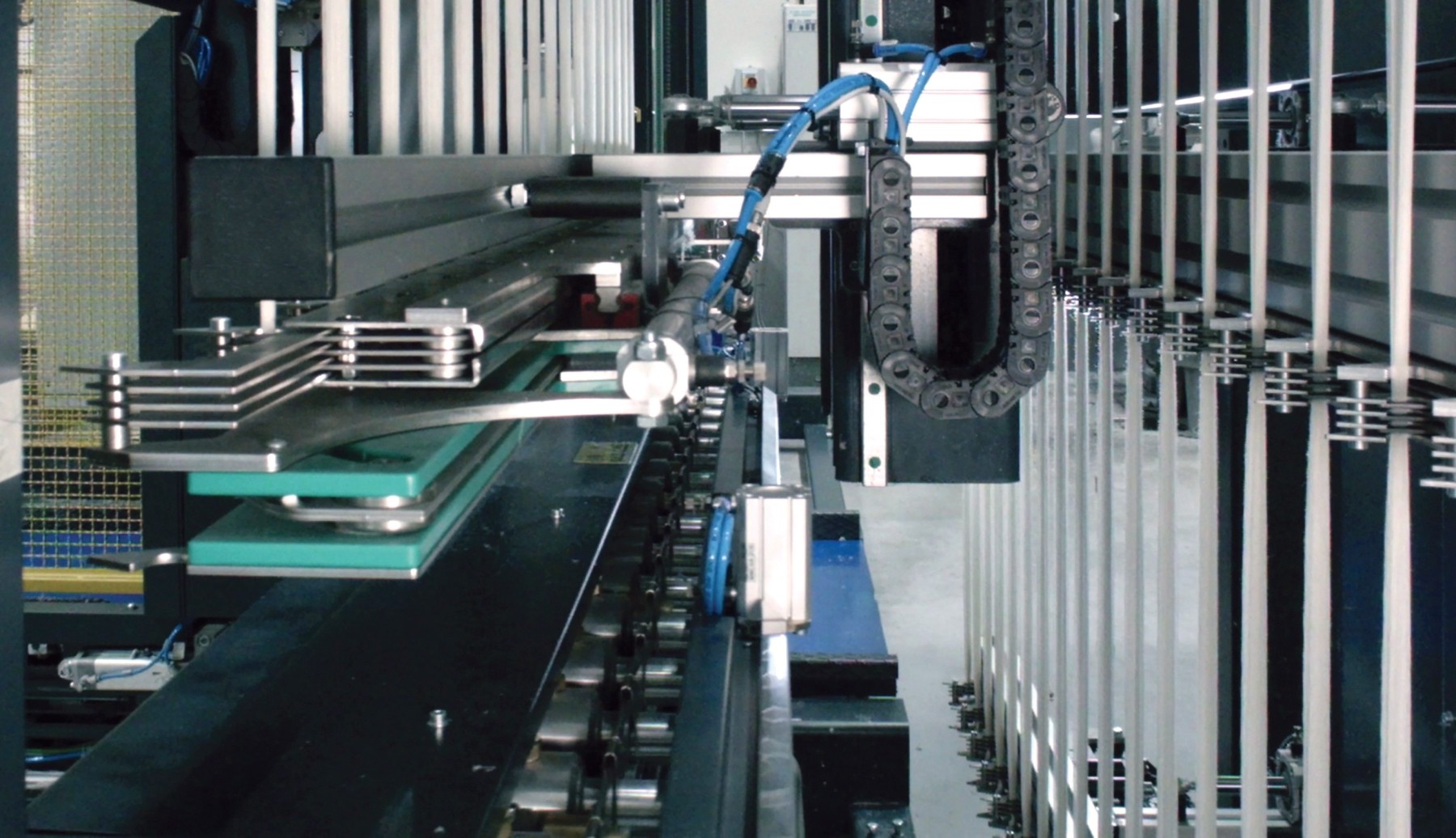

Efficient technology package for plaster grid production

Equipment for warp preparation and fabric production for the plaster grid industry from a single source - from KARL MAYER

Read more

Annual production of 1,000 drying cylinders

The Textile Drying Profit Center of the KARL MAYER Group ended the year 2021 with a milestone

Read more

Gentle handling of finest glass fibers

With the optimized ACCUTENSE TYPE C to ultra-fine, high-quality glass fabrics for the printed circuit board industry

Read more

Fit for the terry cloth market

The new ISO COTTON combined with the TM 4-TS EL sets new standards in the production of terry cloth

Read more