Welcome to KARL MAYER's world of sustainability

The 2024 KARL MAYER jacquard calendar shines a light on sustainability Learn moreThe KARL MAYER GROUP is a family business with a long tradition and a strong sense of social responsibility. Since the company cares about a future worth living, it acts in harmony with social and environmental goals and is guided by Environmental Social Governance (ESG) standards.

Topics:

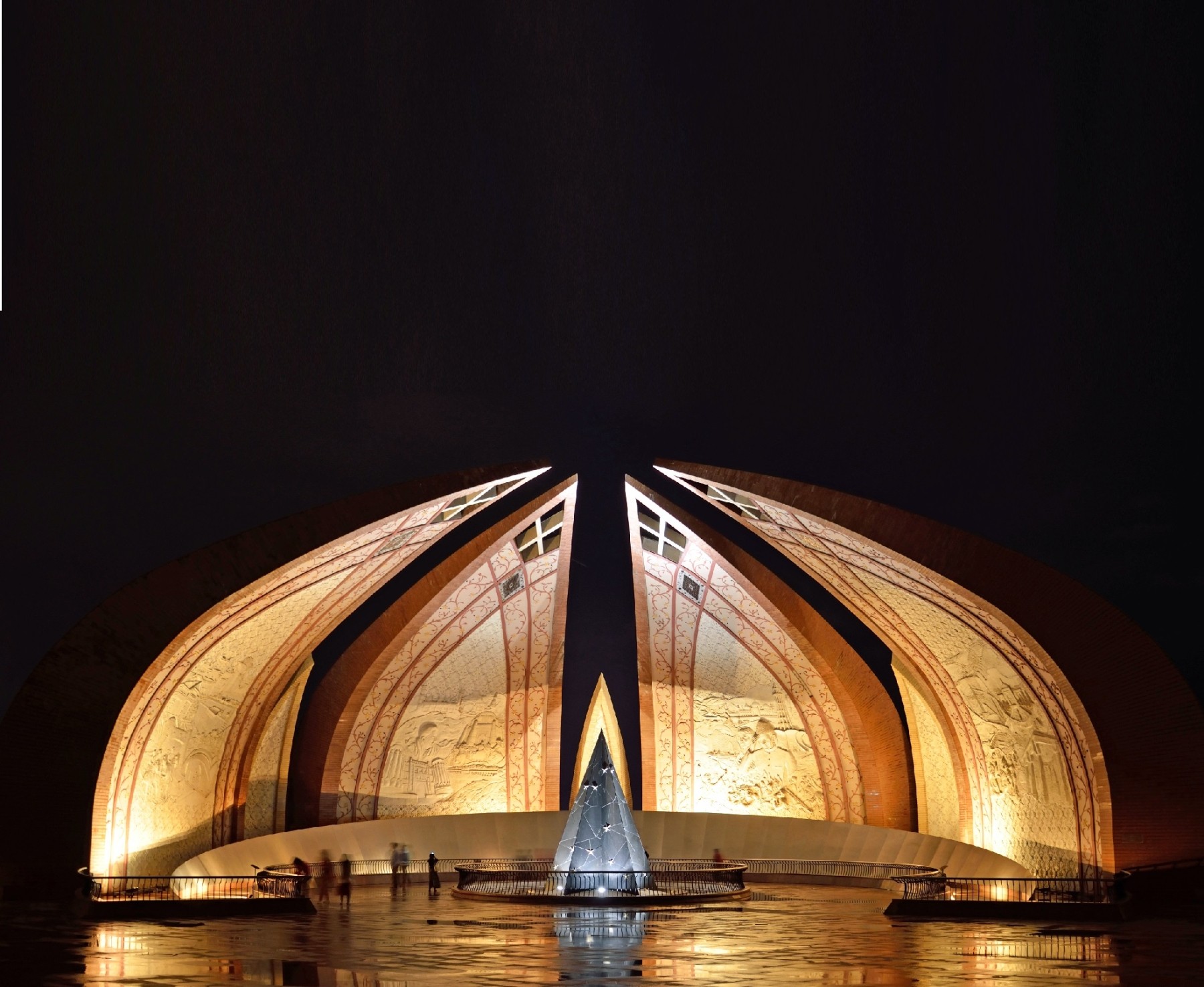

With its jacquard calendar for 2024, the KARL MAYER GROUP is also highlighting the issue of sustainability in a visually effective way. The futuristic design paints a picture of our world that inspires hope and – through its diversity – optimism for the future.

Design image of the header of the calendar, below the monthly, weekly and daily overviews

As in previous years, the Albani Group was once again responsible for designing and producing this year’s KARL MAYER jacquard calendar.

The commitment of the KARL MAYER GROUP to sustainability extends from products and services to the company’s own value creation and the buildings in which business is conducted. As an example, the climate of the new headquarters is controlled by regenerative building technology, featuring heat pumps and a ventilation system with heat recovery at its core. By working largely without paper, an entire storey was not required.

The KARL MAYER GROUP's ultra-modern company headquarters in Obertshausen

Plans are currently underway to install solar panels to supply energy at the Obertshausen site.

The KARL MAYER GROUP is primarily focusing on energy and resource consumption to offer machines with a low ecological footprint. The latest generation of tricot machines features an energy-efficient direct drive and uses pattern data from the cloud instead of metal pattern discs. In addition, customers can monitor and manage the energy consumed by their machines.

The latest ADF flat knitting machines from STOLL also use significantly less energy since they feature new, innovative knitting needles and advanced cam boxes. Additionally, optimised central lubrication reduces oil consumption, and a new oil container under the machine collects used oil for reuse after suitable filtration.

Tricot machine of the latest, digital generation

In warp preparation, a nitrogen-based indigo dyeing system and technology optimisations are impressive, thanks to lower yarn waste, chemical use and water consumption in the final washing process. This innovative system is called BLUEDYE. It is the first unit in the BLUELINE category, under which the KARL MAYER GROUP is now managing all its machines and solutions with a proven contribution to sustainability.

The new VARIO WEFT laying system for KARL MAYER's weft insertion machines

When it comes to producing technical textiles, a weft-insertion machine with the new VARIO WEFT laying system offers production with considerably less edge waste.

Digital solutions also contribute effectively to increased sustainability and economic efficiency at the same time. As an example, the latest k.innovation CREATE DESIGN software for flat-knitted fabrics can interact with any 3D software. To this end, realistic 3D renders can be created, thereby enormously reducing the need for physical patterns and, by extension, lowering material consumption.

Registernow for free to get access to more interesting content