Diverse solutions for the needs of a volume market

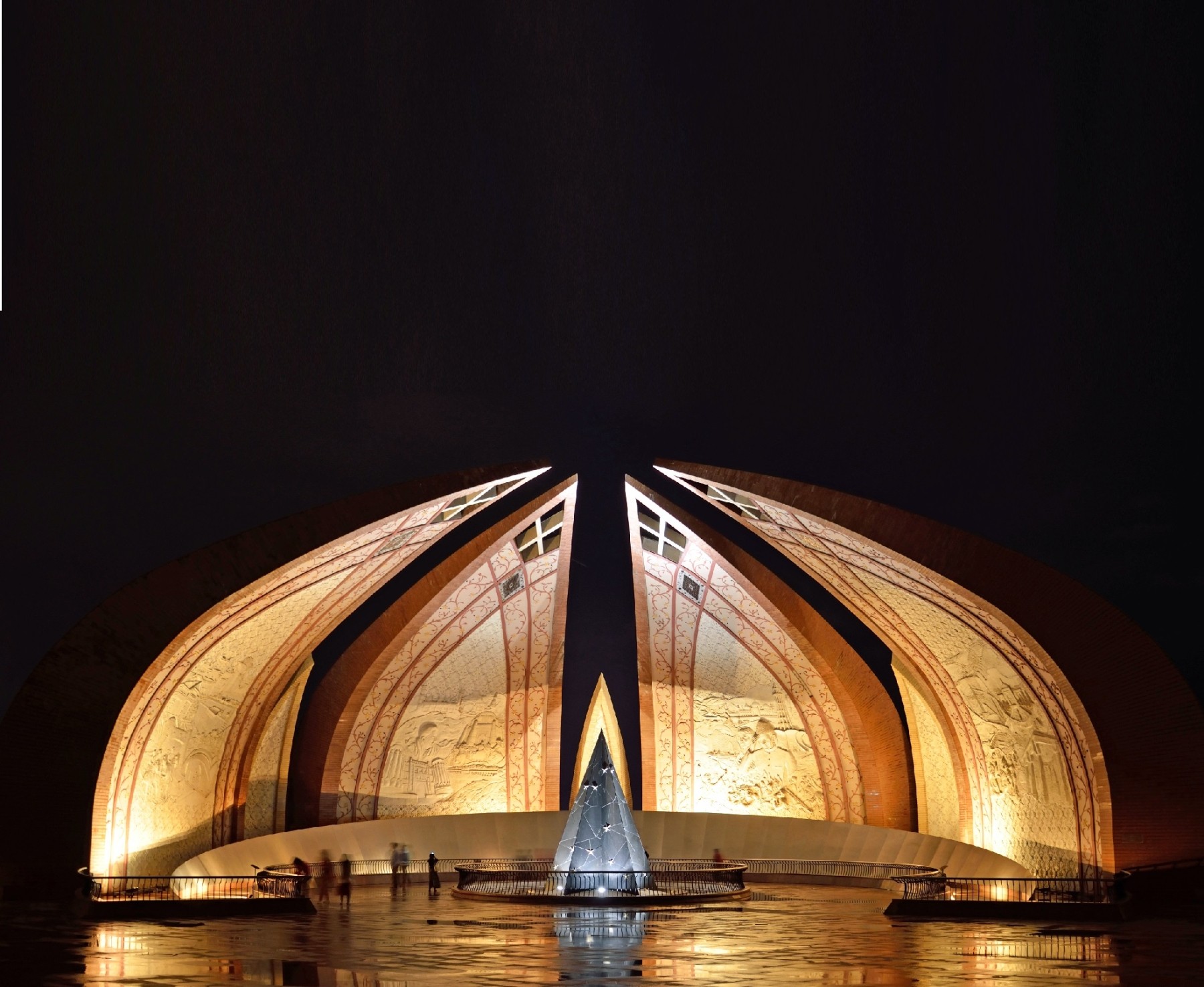

The KARL MAYER GROUP will be travelling to INDIA ITME 2022 highlighting various topics of textile engineering, technical textiles, digitization and care solutions. Learn moreFrom December 8 to 13, INDIA ITME 2022 invites textile professionals to the India Expo Centre & Mart exhibition and convention center in Greater Noida. In recent years, the textile machinery fair has firmly established itself as an international sourcing platform and a place for exchange. The number of exhibitors has increased by 24% and the number of visitors by 10% from 2015 to 2019. The occupied hall space has increased by 30%. After a long corona-related contact restriction, everyone involved is looking forward to the personal get-together, including the KARL MAYER GROUP.

Topics:

The renowned group of companies will be presenting its brands KARL MAYER, STOLL and KM.ON in Hall 15 / H15 C10 D9. The exhibits will focus on the technologies of warp knitting, flat knitting and warp preparation, as well as the production of technical textiles. On show will be textile product and application developments with promising market potential, forward-looking digital solutions for greater process efficiency, and Care Solutions offerings to minimize the effort involved in machine operation. Of course, innovative machines will be presented including a sectional warping machine, produced in and for India, and two STOLL flat knitting machines, whose price-performance ratio perfectly meets the needs of the price-sensitive Indian market.

WARP KNITTING

KARL MAYER's warp knitting business unit will present a comprehensive textile and apparel show, offering inspiration and ideas for new business in the specific environment of the Indian market. The focus here is on comfortable, environmentally friendly and creative fabrics for a wide variety of applications. There will be inspiration not only for knitters but also for weavers.

cotton and bamboo fibers, and an outer side of microfibers for a soft touch. The textile was created on a TM 4-TS EL, environmentally friendly and highly efficient. The warp knitting technology does not require sizing, generates less waste and uses fewer resources compared to weaving. A study by Gherzi shows that around three times less energy is required in the main process alone, textile surface formation. In addition, up to 300% higher output is possible, depending on the weight of the terry fabrics.

Chic, comfortable clothing can also be produced more sustainably and efficiently, as shown by a shirt with a woven fabric-like look and a jacket and pants made from 4-way stretch warp knitted fabrics. The fashion items are extremely comfortable due to the natural elasticity of knitted fabrics. The use of the polyester bi-component yarn LYCRA® T400® provides even more comfort stretch giving a 4-way stretch fabric. Other advantages include easy care and economical production. For the pure production of trouser fabrics, warp knitting machines require only around one-tenth of the energy consumed by weaving machines, according to the Gherzi study.

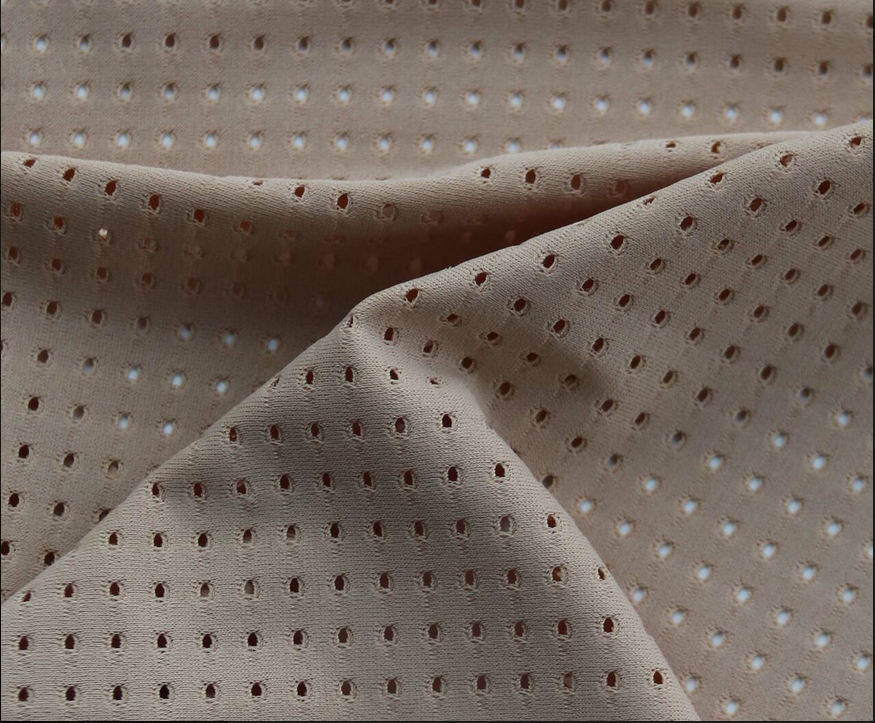

In addition, innovative sportswear outfits will be shown at INDIA ITME: an original dress made from a standard spacer fabric produced on an RD 6/1-12 and leggings made from power jersey from an HKS 2-SE PLUS with a pleasant feel, clean-cut design and the excellent stretch behavior due to the twill stitch. Other sportswear exhibits include shorts made from a lightweight and breathable mesh knitwear as well as plain and smooth jersey goods.

WARP PREPARATION

The highlight for the trade show guests from the warp preparation sector will be a performance show of the ISOWARP. The sectional warping machine combines the group's proven high quality with the advantages of local production. The model is built at KARL MAYER India in Ahmedabad.

It processes staple and filament yarns of all types, offering maximum performance at low overall cost to the investor, and produces quality beams that enable maximum efficiency in the weaving mill. Another plus point is simple, safe operation, even by personnel with only basic training. The performance profile and the advantages of on-site production - including prompt, competent service and the best spare parts supply - are well received. According to Kevin Socha, Managing Director of KARL MAYER Hong Kong, manufacturers from the apparel sector are particularly interested in ISOWARP. Articles made of filament yarns are currently booming here, but the first manufacturers of technical woven fabrics are also asking for a pragmatic sectional warping machine.

Other exhibition focal points include illustrative and informational materials on the top themes of denim, sizing and sample warping.

FLAT KNITTING

For the flat knitting sector, the KARL MAYER GROUP is offering a machine show with no less than two attractively priced, high-performance models. The BMS 52 ki multi gauge E 3.5.2 is designed for entry-level knitting in the STOLL world. The basic flat knitting machine produces fully fashion and cut & sew articles for the mass market and impresses with its excellent price/performance ratio. The costs in terms of purchase, spare parts and operation are extremely competitive - while at the same time offering the highest quality. The quality meets the high standards of all STOLL products. Other advantages include optimum interaction with all STOLL-knitelligence® components and networkability. In addition to the BMS model itself, various of its fully fashion products will be on display.

The second machine presented is a CMS 503 ki multi gauge E 7.2. The proven CMS product expands the STOLL Economic range, which stands for higher productivity, and focuses on the price sensitivity of Indian customers in terms of costs. The all-rounder also impresses with its flexibility. Articles are produced for a wide range of applications and with the highest quality, as shown at the trade fair, for example, by a peacock design with weave-like effects and an article with a jacquard pattern, created with purl structure in two colors. The specification of the CMS 503 ki multi gauge E 7.2 also includes a knitelligence® generation control system and networking capability.

"With our exhibition machines, we are demonstrating a sense of proportion for the right products on the Indian market."

KARL MAYER STOLL India in Noida also supports its customers with service offers, training courses and technician assignments.

TECHNICAL TEXTILES

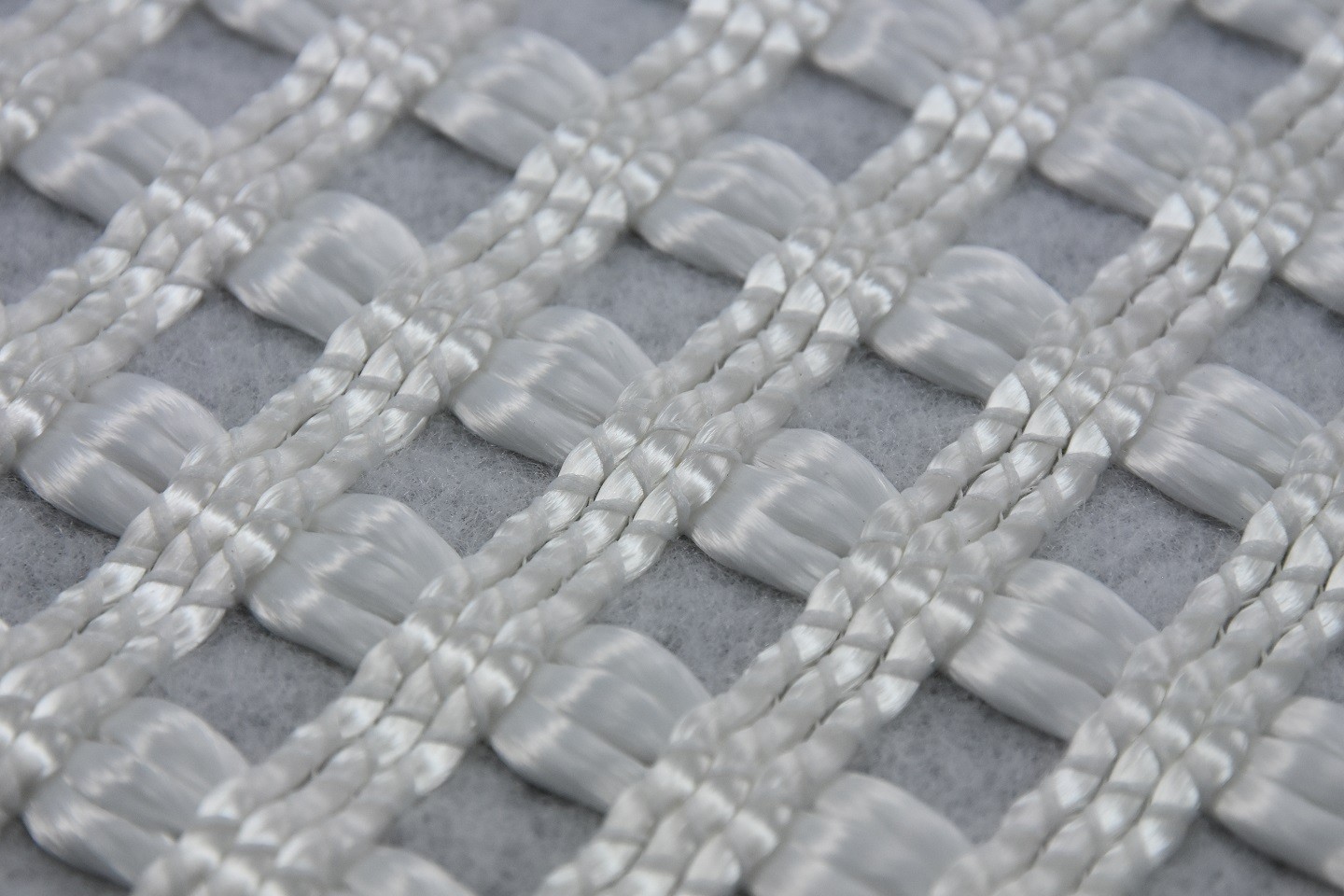

The KARL MAYER exhibition for technical textiles will focus on the growth markets of infrastructure and construction. Geogrids from weft knitting machines are already firmly established in Indian road construction and promise to continue doing good business. India operates the second largest road network in the world. Gigantic government infrastructure projects are intended to further develop the country for train and private transport. The grid structures, almost exclusively made of polyester, are produced extremely efficiently, above all on the WEFTTRONIC® II G weft knitting machine. The model can replace up to 25 weaving machines, thus, saving personnel and space.

Another promising market is the wind power sector. In order to achieve its climate protection targets, India wants to install wind turbines with a capacity of 140 GW by 2030. Composites with fabrics from multiaxial machines, mainly from KARL MAYER, are processed in the rotors of the windmills. Composites with reinforcing fabrics are also in demand in the mass transportation sector, for example in the construction of cabins for trains.

DIGITAL SOLUTIONS

KM.ON's digital solutions open up the possibilities of smart manufacturing to customers. The focus at INDIA ITME will be on the k.management Dashboard and k.innovation CORE.

The k.management dashboard uses near-time data to provide an overview of key data for planning upcoming tasks and available capacity - anytime, anywhere.

With k.innovation CORE, the implementation of designs becomes extremely flexible and simple. All the customer has to do is log on with an Internet-enabled device, select a machine type, enter the lappings for the individual ground guide bars, create the pattern file with just a few clicks and send it to the KM.ON cloud. The lapping file is then selected on the user interface of the machine in question. In addition, the web-based software offers collaboration options to speed up development processes.

Another software exhibit from KM.ON include k.innovation CREATE DESIGN for a faster design-to-market workflow in flat knitting.

CARE SOLUTIONS

The KARL MAYER GROUP's Care Solutions team is launching a regional extension of the tried-and-tested KARL MAYER WEBSHOP for the warp preparation business unit at the INDIA ITME. Customers in India can now order spare parts for their warp preparation machines at the click of a mouse. The most important wear and spare parts are available for the most common models on the local market. The parts that can be ordered are kept in stock at KARL MAYER India in Ahmedabad. On-site stocking and ordering by computer ensure that supplies are delivered in the shortest possible time. In addition, there are no risks due to the exchange rate, as payment is made in the local currency.

Registernow for free to get access to more interesting content