Machine premiere and new business potential

for Technical Textiles

Innovative solutions for the composite sector and the production of grids

Learn more

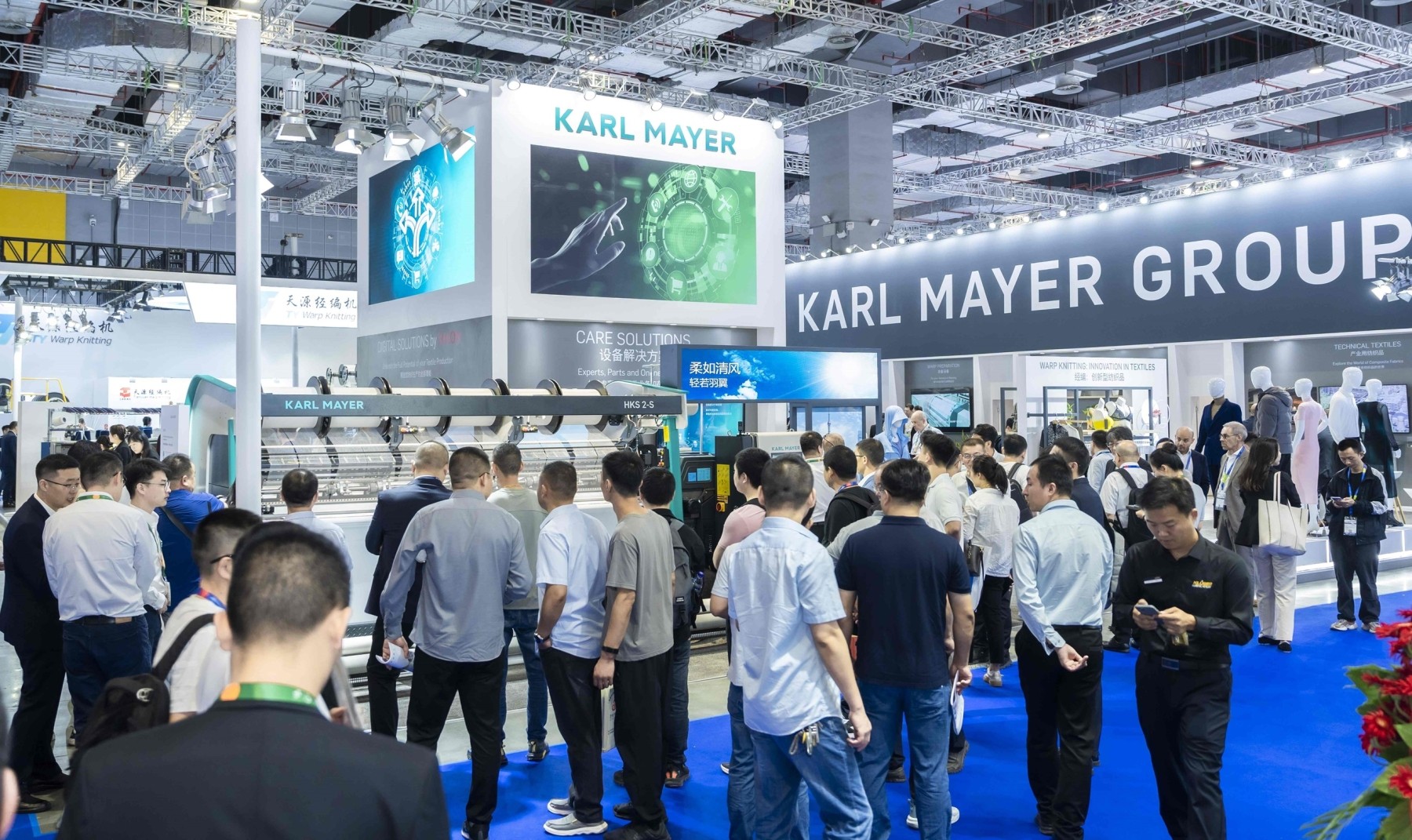

The technical textiles sector offers lucrative opportunities for specialized manufacturers, but also for conventional textile companies that want to diversify. The KARL MAYER GROUP will be demonstrating how this promising potential can be exploited with its presence at the upcoming ITMA ASIA + CITME.

This article is about:

Carbon fabrics for lucrative applications

The innovative global player's exhibition in Shanghai clearly focuses on developments in the carbon market. In hall 4, at stand C27 of the Shanghai National Exhibition and Convention Center, tailor-made reinforcement textiles will be presented, which can be used in a wide range of lightweight construction applications.

“The demand for carbon composites has increased significantly in recent years, particularly in Asia. We are looking forward to talking to traditional warp knitting customers who want to expand their offering, as well as new customers who want to gather information on applications with these high-performance composite materials.”

At KARL MAYER, they will not only find the right multiaxial warp knitting machine for the production of high-performance reinforcement fabrics for composite materials but will also receive useful know-how gained from years of experience.

Warp knitting machines with weft insertion and a convincing price-performance ratio

In addition to the textile and application show in Shanghai, there will be a machine presentation during an in-house show accompanying the trade fair at KARL MAYER (CHINA) in Changzhou. The event begins on October 13. Two innovative warp knitting machines with weft insertion aimed at the volume market will be on show: a 2nd generation TM WEFT for the production of lightweight fabrics with weft insertion for outerwear fabrics and interlinings and the newly developed WEFT GRID ECO machine.

The TM WEFT was included in the exhibition program due to the high demand and positive feedback during the last in-house show. On display will be a machine with a 247” working width, carbon bar equipment and functional optimization. Thanks to the advanced development of the crank box system, a 20% increase in performance has been achieved with the new release. The TM WEFT will be producing an outerwear article during the in-house show.

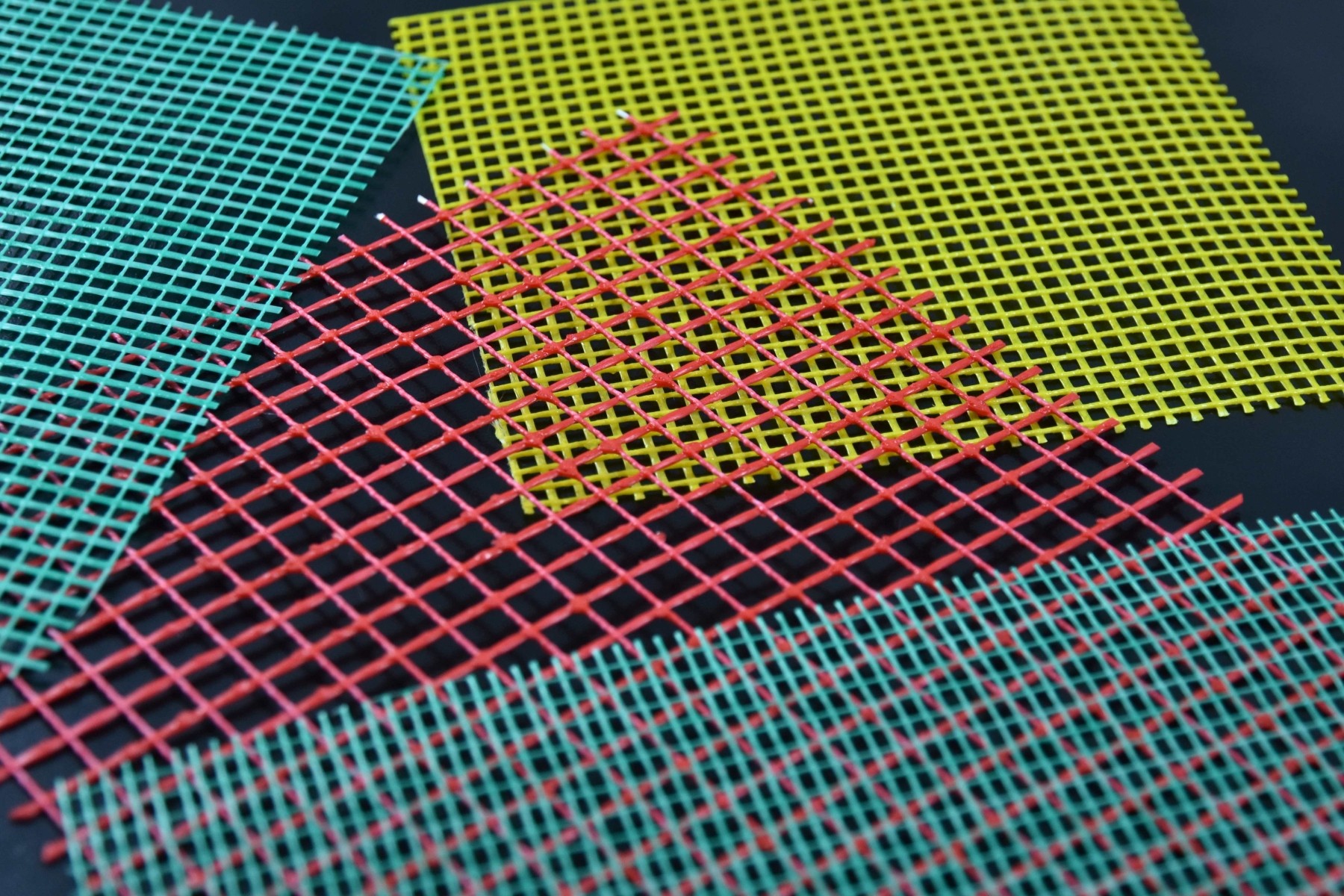

The new WEFT GRID ECO is specified for the efficient production of “light” glass grid structures from materials with gauges of up to 400 tex in the weft inlay and warp inlay thread area. These textiles are mainly used in the construction industry, for example as plaster grids or crack tape. When developing the machine, the focus was more than ever on the price-performance ratio.

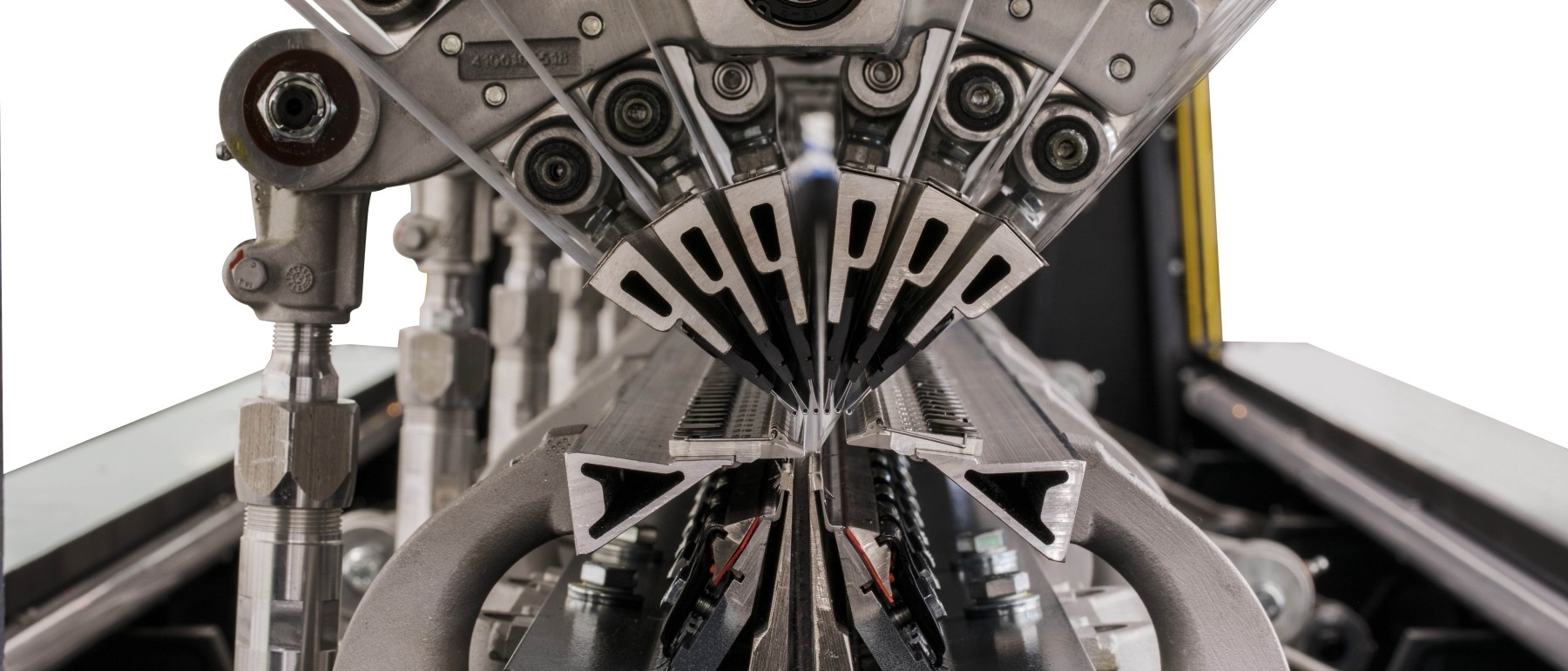

Weft insertion system of the new WEFT GRID ECO

“The working width is 245“, and the speed is 1,800 rpm, making the WEFT GRID ECO up to 12% faster and 20% cheaper than our all-purpose machine WEFTTRONIC II G.”

Plaster grid from a warp knitting machine with weft insertion

The Sales Manager is looking forward to the first participation in a major international trade fair in Asia since the coronavirus pandemic. In addition to Chinese customers, he is expecting a large international audience.

Registernow for free to get access to more interesting content

Successful start

to the trade fair

Register now

Machine premiere and new business potential

for Technical Textiles

Register now

New double raschel machine impresses with its price-performance ratio

Register now- What’s new in warp knitting?

-

Digital solutions for the challenges of

warp knitting and

knittingmills - Lighthouse solutions for the challenges of our time

-

Pulling out all the

stops when it comes

to wearing comfort - Managing energy instead of wasting it

- Microfactory with mega-effects for the future

-

In close pursuit of

the Leavers look - Net pioneer on course for expansion

- New Power net production machine sets standards in terms of price-performance ratio

-

Defence is worthwhile, especially in the case

of product piracy! -

Quality monitoring

with added value

through AI -

Manage digitally,

enhance efficiency

with the DPM for warp knitting - A game changer in warp knitting shop floor management

- Quality control on a new level - the new AI-based Quality Monitoring System (QMS)

- Rethinking civil engineering business with warp-knitted fabrics with weft insertion and non-crimp fabrics

- Lots of visitors, good discussions, a look at the trends

- New business momentum for the Turkish warp knitting industry

-

First energy efficiency solution

for warp knitting

machines - Transparency for energy efficiency

- To fly the flag in East Asia

-

Electrifying

opportunities for new

business potential - Green prospects for composites

-

Being

on the right track - KARL MAYER TURKEY appoints General Manager

- Just as important as a threading hook!

- Successful start for a four-bar high-speed all-rounder in the tricot market

- Innovations with push effects

- Flexibility makes the difference

- New TEXTRONIC® Lace for the most Leavers-like lace in warp knitting

- Taking off with more speed and flexibility in the tricot machine sector

- Moving closer together in uncertain times

- New multifunctional RASCHELTRONIC® expands market opportunities

- Skin protection the textile way

- Innovations – more than just inventions

- A company shows its colours

- Vehicle interiors undergo change

- Platform for knowledge exchange in India

- Help for the daily work routine

- Net capable

- Spacer fabrics for the automotive future

- Naturally beautiful

- Fabric trends at the top level

- service4you

- A machine that KARL MAYER is proud of

- Flexible in all directions, comfortable for any occasion

- Networks for a good urban climate

- Mastering a hairy affair

- Celebrate beauty by lace

- Record interest from a market on the upswing

- SUIT YOURSELF

- Sunny business prospects in Africa?

- Raschel machines with more diversity and a digital generation HKS with performance upgrade

- Flexible warp knitting machine with weft insertion and more

- Introducing new swimwear fabric for circularity

- High up with green nets

- Care Solutions for perfect all-round support

- KARL MAYER GROUP and Lenzing Group collaborate

- Master the Change with digital solutions

- Fishnets from a real insider

- Keep cool on hot nights

- Performance warp knits are bringing the future to the piste

- From old to new

- Train on site, maximise benefits

- From the machine to the printing table

- Beastly good imitation fur

- Lace that spices up our lives

- A Market in Motion

- HI-TECH CROCHET – skin- friendly magic

- Successful start to training courses in India

- Warp knitting expertise for the USA

- Saving energy through warp knitting

- Next generation bio-derived LYCRA® fiber

- Collections that provide FURORE

- “Clothes maketh the man”

- Customised, cost-effective implant solutions

- Warp knitting between market shifts and climate change

- More lapping variety, more shape power

- What will happen in the next 15 years?

- A machine with many faces

- New patterning dimensions with the HKS digital generation

- Organic is sexy

- Greater variety of widths for more precise market tailoring

- Seducer with environmental awareness

- Two styles, one look

- Patterning from the cloud

- Transparency for efficiency

- Bar changing – made easy

- KARL MAYER opens service office in Surat

- Full service packages for machine operation

- Warp-knitted textiles always cut a fine figure

- Efficient technology package for plaster grid production

- Speed PLUS variety in elastane processing

- Securing a head start with digitalization

- Fit for the terry cloth market

- Comfortable and sustainable

- Made for you

- Quantum leaps in patterning

- Dissolving design boundaries

- Beautiful and comfortable

- Colourful fun on the beach and by the pool