Machine premiere and new business potential

for Technical Textiles

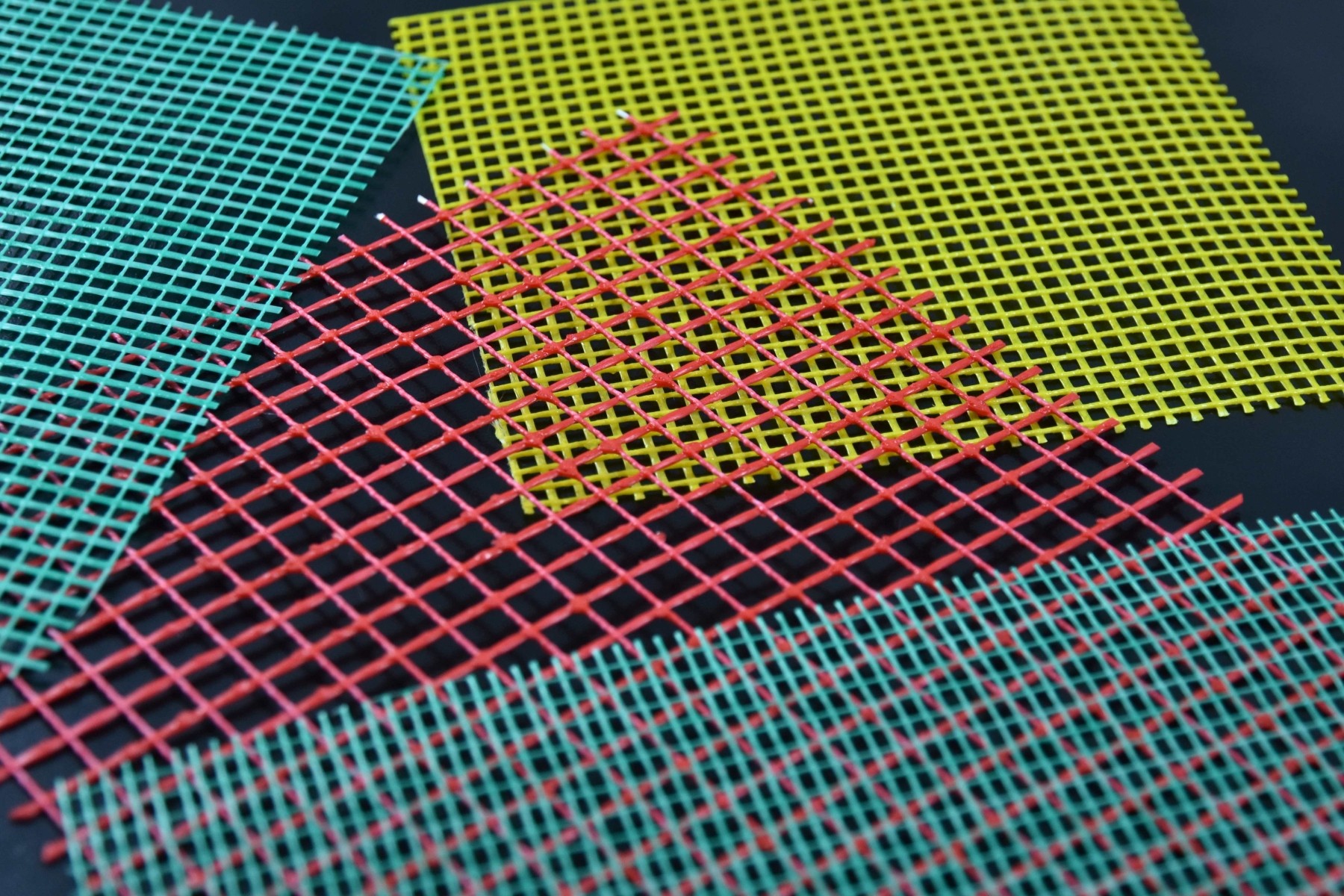

Innovative solutions for the composite sector and the production of grids

Learn more

The technical textiles sector offers lucrative opportunities for specialized manufacturers, but also for conventional textile companies that want to diversify. The KARL MAYER GROUP will be demonstrating how this promising potential can be exploited with its presence at the upcoming ITMA ASIA + CITME.

This article is about:

Carbon fabrics for lucrative applications

The innovative global player's exhibition in Shanghai clearly focuses on developments in the carbon market. In hall 4, at stand C27 of the Shanghai National Exhibition and Convention Center, tailor-made reinforcement textiles will be presented, which can be used in a wide range of lightweight construction applications.

“The demand for carbon composites has increased significantly in recent years, particularly in Asia. We are looking forward to talking to traditional warp knitting customers who want to expand their offering, as well as new customers who want to gather information on applications with these high-performance composite materials.”

At KARL MAYER, they will not only find the right multiaxial warp knitting machine for the production of high-performance reinforcement fabrics for composite materials but will also receive useful know-how gained from years of experience.

Warp knitting machines with weft insertion and a convincing price-performance ratio

In addition to the textile and application show in Shanghai, there will be a machine presentation during an in-house show accompanying the trade fair at KARL MAYER (CHINA) in Changzhou. The event begins on October 13. Two innovative warp knitting machines with weft insertion aimed at the volume market will be on show: a 2nd generation TM WEFT for the production of lightweight fabrics with weft insertion for outerwear fabrics and interlinings and the newly developed WEFT GRID ECO machine.

The TM WEFT was included in the exhibition program due to the high demand and positive feedback during the last in-house show. On display will be a machine with a 247” working width, carbon bar equipment and functional optimization. Thanks to the advanced development of the crank box system, a 20% increase in performance has been achieved with the new release. The TM WEFT will be producing an outerwear article during the in-house show.

The new WEFT GRID ECO is specified for the efficient production of “light” glass grid structures from materials with gauges of up to 400 tex in the weft inlay and warp inlay thread area. These textiles are mainly used in the construction industry, for example as plaster grids or crack tape. When developing the machine, the focus was more than ever on the price-performance ratio.

Weft insertion system of the new WEFT GRID ECO

“The working width is 245“, and the speed is 1,800 rpm, making the WEFT GRID ECO up to 12% faster and 20% cheaper than our all-purpose machine WEFTTRONIC II G.”

Plaster grid from a warp knitting machine with weft insertion

The Sales Manager is looking forward to the first participation in a major international trade fair in Asia since the coronavirus pandemic. In addition to Chinese customers, he is expecting a large international audience.

Registernow for free to get access to more interesting content

Machine premiere and new business potential

for Technical Textiles

Register now

Lighthouse solutions for the challenges of our time

Register now

Pulling out all the

stops when it comes

to wearing comfort

Register now

- New cost-benefit champion in glass processing

- Rethinking civil engineering business with warp-knitted fabrics with weft insertion and non-crimp fabrics

- Lots of visitors, good discussions, a look at the trends

- Waiting for an upwind

-

Electrifying

opportunities for new

business potential - Digitalization brings movement to the sports, fitness and wellbeing sector

-

Master the change

with solutions from the KARL MAYER GROUP - Green prospects for composites

-

Being

on the right track - Bionic oil adsorber helps protect waters

- Vehicle interiors undergo change

- Net capable

- Spacer fabrics for the automotive future

- Networks for a good urban climate

- Record interest from a market on the upswing

- Flexible warp knitting machine with weft insertion and more

- High up with green nets

- Fishnets from a real insider

- Nets for big fish

- World's first carbon concrete building stands

- Forging ahead on spacer fabrics

- Gladly worn instead of necessary load

- Early rider in the use of natural fibres

- Efficient technology package for plaster grid production

- Greater energy efficiency in greenhouse growing

- Warp knitted solutions with great leverage