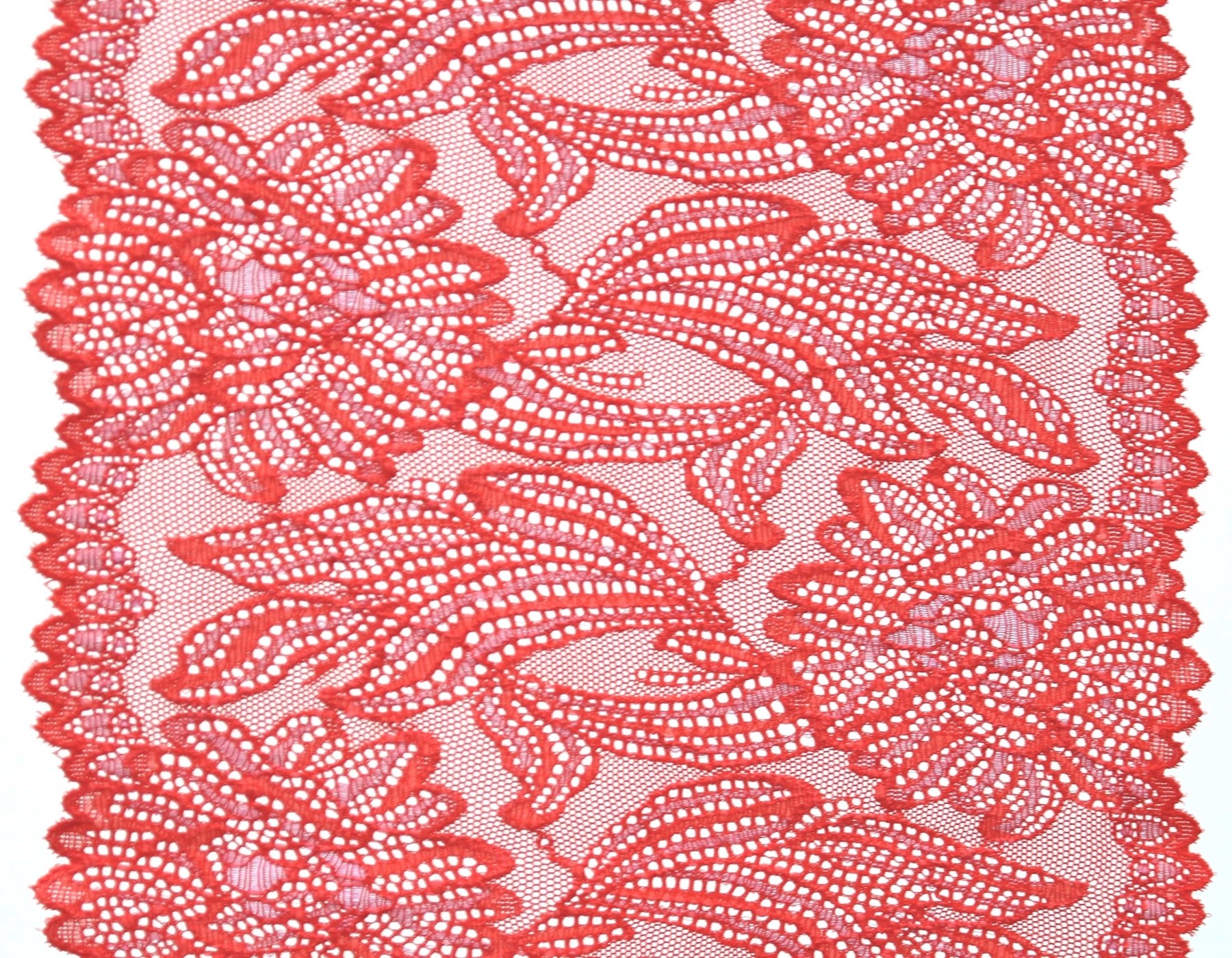

In August last year, KARL MAYER launched the new MJ 92/1 F, bringing a new breeze to the lingerie sector. The JACQUARDTRONIC® LACE can create completely new textile surfaces, particularly thanks to Symm-Net, a patterning technique for producing lace with a filigree, extremely precise pattern and maximum symmetry of the design elements. As a result, Symm-Net articles come closer than ever before to the benchmark of Leavers lace.

This article is about:

"In terms of appearance, we have already previously achieved 90% of the Leavers appearance and now we are even closer. The richness of effect, clarity and symmetry of the design of the MJ 92/1 F lace are unsurpassed."

The variety is also great. If the Symm-Net variants are combined with different multi-bar structures, the range of typical pattern styles that can be imitated can be extended considerably. Completely new designs are also possible.

In his latest work, Jamie Heather uses the potential of front-placed jacquard bars, clever, ground-breaking drafting techniques and typical Leavers yarns - such as fine, twisted cotton - to radically rethink the theme of JACQUARDTRONIC® lace. His creations show the brilliant design appearance of Symm-Net and at the same time pattern effects with a previously unattained complexity. Simultaneously, all conventional JACQUARDTRONIC® articles can be produced on the MJ 92/1 F without any mechanical modifications.

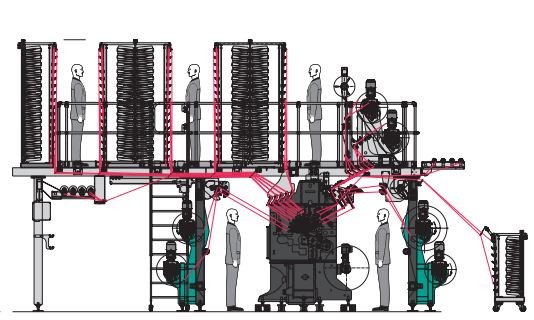

MJ 92/1 F

Jacquard bar front, compatibility back

The MJ 92/1 F offers differences compared to its B counterpart, which can prove to be advantages depending on the application. Generally speaking, handling on the machine is easier during patterning. Hardly any corrections need to be made to the jacquard when working in new patterns, typically something that is regularly required on machines with the Jacquard at the back.

The fact that the jacquard yarns run vertically into the jacquard bars is a key factor, making tension ranges greater and drafting easier.

In addition, the loose Jacquard tension also improves the look of the lace.

The F version scores further points when working clip patterns: the floating yarns are laid on the back of the fabric and straight. This results in an extremely clean fabric appearance, without any annoying clip ends showing as we clip on the back of the lace on an F-machine. If the clip patterning is done on standard jacquard construction, stripes can often be visible in the wales where the floating yarns lie. This effect can be significantly minimized with Symm-Net technology - an advantage that is particularly beneficial when clipping behind fine lace structures.

A special twist also makes it possible to create looks with strikingly dimensional liners – normally a specialty of the B variant. As the jacquard flattens the dimensionality of the lines on an F machine, the elastane is used on the front of the machine instead of the back and the lace is made effectively backwards. The liners are threaded at the very back of the machine and the finer yarns directly behind the jacquard. After finishing, the lace is turned and the backside becomes the selling face, allowing B goods to be produced on an F machine.

"All standard JACQUARDTRONIC® articles can also be produced on the MJ 92/1 F without any changes to the machine from the Symm Net set-up. This compatibility of the product portfolio is a real customer benefit!"

Crève-Cœur imitation with more variety

Using the possibilities offered by the MJ 92/1 F, Jamie Heather developed a series of lace designs in which he imitated the typical Leavers Crève Cœur ground.

When creating this ground structure, he used the regular pillar bar and a split-thread jacquard bar in addition to two ground guide bars for elastane at the back imitating the symmetry of the jacquard.

Thanks to Symm-Net drafting and the use of Leavers-style pattern yarns, the Crève-Cœur construction is strikingly clear and uniform.

Jamie Heather also based the style of the lace on the expected fashion trends for next year. "I developed traditional lace with a slightly abstract pattern for my MJ 92/1 F project. The motifs show small irregularities, a touch of a modern Leavers look," says the lace expert.

His lace project started in January 2024, and by June he had already produced 15 samples, each with Symm-Net technology and in conventional design, to illustrate the differences.

Further steps are already planned. Next, Jamie Heather wants to use cotton in the jacquard and experiment with a chemical lockstitch to prevent the all-too-common slippage issues. Rigid, fine, high-quality Chantilly fabrics for the outerwear sector are in the works.

Registernow for free to get access to more interesting content

Pulling out all the

stops when it comes

to wearing comfort

Register now

Managing energy instead of wasting it

Register now

Microfactory with mega-effects for the future

Register now-

In close pursuit of

the Leavers look - Net pioneer on course for expansion

- New Power net production machine sets standards in terms of price-performance ratio

-

Defence is worthwhile, especially in the case

of product piracy! -

Quality monitoring

with added value

through AI -

Manage digitally,

enhance efficiency

with the DPM for warp knitting - A game changer in warp knitting shop floor management

- Quality control on a new level - the new AI-based Quality Monitoring System (QMS)

- Rethinking civil engineering business with warp-knitted fabrics with weft insertion and non-crimp fabrics

- Lots of visitors, good discussions, a look at the trends

- New business momentum for the Turkish warp knitting industry

-

First energy efficiency solution

for warp knitting

machines - Transparency for energy efficiency

- To fly the flag in East Asia

-

Electrifying

opportunities for new

business potential - Green prospects for composites

-

Being

on the right track - KARL MAYER TURKEY appoints General Manager

- Just as important as a threading hook!

- Successful start for a four-bar high-speed all-rounder in the tricot market

- Innovations with push effects

- Flexibility makes the difference

- New TEXTRONIC® Lace for the most Leavers-like lace in warp knitting

- Taking off with more speed and flexibility in the tricot machine sector

- Moving closer together in uncertain times

- New multifunctional RASCHELTRONIC® expands market opportunities

- Skin protection the textile way

- Innovations – more than just inventions

- A company shows its colours

- Vehicle interiors undergo change

- Platform for knowledge exchange in India

- Help for the daily work routine

- Net capable

- Spacer fabrics for the automotive future

- Naturally beautiful

- Fabric trends at the top level

- service4you

- A machine that KARL MAYER is proud of

- Flexible in all directions, comfortable for any occasion

- Networks for a good urban climate

- Mastering a hairy affair

- Celebrate beauty by lace

- Record interest from a market on the upswing

- SUIT YOURSELF

- Sunny business prospects in Africa?

- Raschel machines with more diversity and a digital generation HKS with performance upgrade

- Flexible warp knitting machine with weft insertion and more

- Introducing new swimwear fabric for circularity

- High up with green nets

- Care Solutions for perfect all-round support

- KARL MAYER GROUP and Lenzing Group collaborate

- Master the Change with digital solutions

- Fishnets from a real insider

- Keep cool on hot nights

- Performance warp knits are bringing the future to the piste

- From old to new

- Train on site, maximise benefits

- From the machine to the printing table

- Beastly good imitation fur

- Lace that spices up our lives

- A Market in Motion

- HI-TECH CROCHET – skin- friendly magic

- Successful start to training courses in India

- Warp knitting expertise for the USA

- Saving energy through warp knitting

- Next generation bio-derived LYCRA® fiber

- Collections that provide FURORE

- “Clothes maketh the man”

- Customised, cost-effective implant solutions

- Warp knitting between market shifts and climate change

- More lapping variety, more shape power

- What will happen in the next 15 years?

- A machine with many faces

- New patterning dimensions with the HKS digital generation

- Organic is sexy

- Greater variety of widths for more precise market tailoring

- Seducer with environmental awareness

- Two styles, one look

- Patterning from the cloud

- Transparency for efficiency

- Bar changing – made easy

- KARL MAYER opens service office in Surat

- Full service packages for machine operation

- Warp-knitted textiles always cut a fine figure

- Efficient technology package for plaster grid production

- Speed PLUS variety in elastane processing

- Securing a head start with digitalization

- Fit for the terry cloth market

- Comfortable and sustainable

- Made for you

- Quantum leaps in patterning

- Dissolving design boundaries

- Beautiful and comfortable

- Colourful fun on the beach and by the pool