How dark could things get when electricity is scarce?

Interview about STOLL, the KARL MAYER GROUP’s business unit for flat knitting machines, and the current situation Learn more

Rising energy costs, supply chain disruptions, skills shortages, lockdowns and a war in the middle of Europe – the problems we are facing now are complex and are pushing many companies to the limits of their resilience. A snap survey conducted by the Federation of German Industries (BDI) in September 2022 shows: 58% of the 600 SMEs surveyed see the price increases for energy and raw materials as a strong challenge, and 34 % even see it as a possible threat to their existence. Delivery difficulties and delays were a severe or existential challenge for about three quarters of the participants in the BDI survey. In view of the significant price increases, around 40% of companies are postponing investments in their ecological and digital transformation.1

What is the situation like now, specifically in textile machinery manufacturing? Do companies in this sector face the same problems? my TEXTILE NEWS editor Ulrike Schlenker investigated these and other questions in an interview with Andreas Schellhammer, President of the KARL MAYER GROUP’s STOLL business unit, who is responsible for the global player’s flat knitting machine business.

This article is about:

People related to this article:

Read More From My Textile News

Get free access to all articles, numerous specials and interviews. Register for freeRegisternow for free to get access to more interesting content

Mastering a hairy affair

Register now

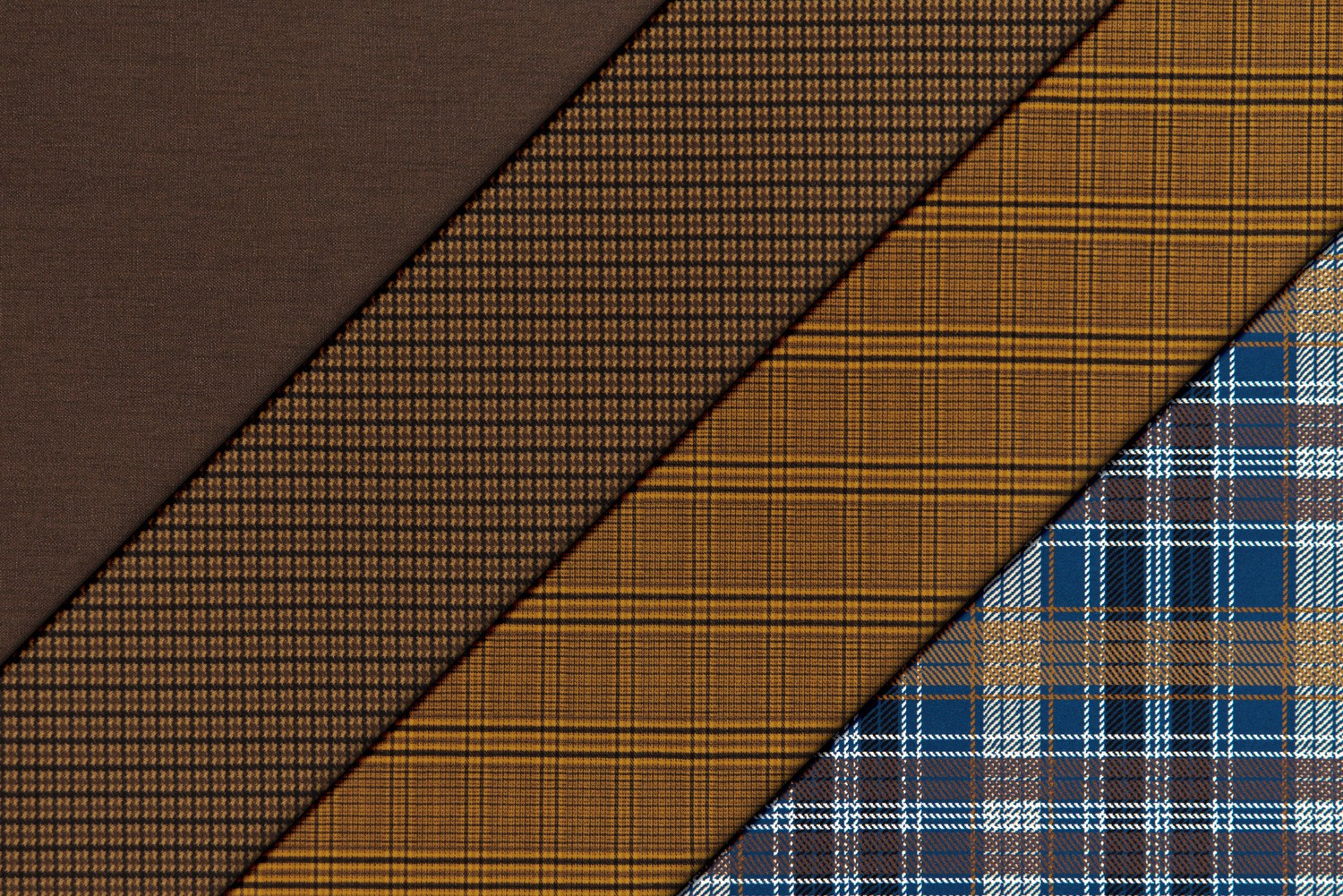

SUIT YOURSELF

Register now